SP-25BD High frequency induction heater

(1) Model: SP-25BD with separated transformer

(2) Maximum input power: 25KW

(3) Output frequency: 30—80KHZ

(4) Heating Current: 10~52A

(5) Input: 380V three phases 50 or 60HZ

(6) Duty cycle: 100%

(7) Connecting cable length: 2 meters

(8) Cooling water desire: ≥0.2MPa ≥6L/min

(9) Weight of generator: 28KG

(10) Weight of transformer: 26KG

(11) Size of generator(CM):55.5L×25.2W×46.2H

(12) Size of transformer(CM): 36L×26W×36H

(13) Used for Tool brazing, etc.

Keyword: induction heater, high frequency brazing machine, melting machine,

DetailsapplicationsotherInstallationDimensions

SP-25BD、SP-35B & SP-45B series are suitable for many applications, for example,

(1)Heat treatment of gear and shaft

(2)Brazing of diamond tools

(3)Brazing of electrical kettle bottom

(4)tube heating for coating

(5)Heating of stainless steel vessel for annealing

(6)brazing of machining tools

(7)Melting of all kinds of metals

(8)Brazing of copper & brass tube and connectors in air conditioner manufacturing factories and so on.

Due to the adopting of our second generation inverting control technology, SP-25BD,SP-35B & SP-45B series machines are acterized with high reliability and low repair cost, and are one of the most popular models and have been used widely in every areas of metal heating.

Advantages and applications of models with Timer function:

1. Heating power, retaining power, heating time, retaining time and cooling time can be preset and adjusted, this makes it possible to control the heating curve and heating time.

2. It is suitable to use in the repeated heating or high speed heating of small parts;

3. When using in brazing, with proper timing parameters, rapid heating and retaining can be achieved to keep the temperature while the brazing material is melted and then to let the brazing material spread smoothly to form good joint.

Advantages and applications of separated transformer:

1. In these three series machines, the high frequency transformer is separated from the generator, with 2 meters connecting cable at least.

2. It is suitable to use in the dirty or corrosive surroundings, the generator can be put in a clean space to increase the reliability.

3. With the small size and light weight of the separated transformer, it is convenient to use in the production line and easily assembled inside the machinery or moved mechanism.

Working theory and structure

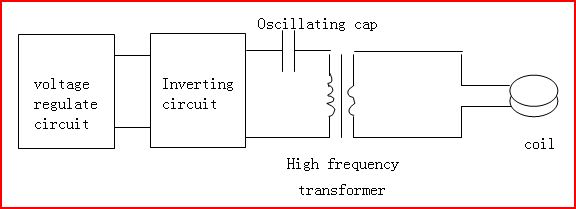

In SP-25BD, SP-35B and SP-45B series machines, series oscillating circuit is applied, through high frequency transformer, low voltage and high current power is output to go through the induction coil.

Inside these series machines, IGBT module and our second generation inverting control technology has been used, that is the dual control and inverting technology. In these new technologies, output power and oscillating frequency are controlled independently. we use IGBT components and high frequency voltage regulate control circuit to control the power and we use IGBT components, series oscillating and automatic tracing circuit to reach soft switching in the inverting course, all these make the machine to be more reliable and make the machine possible to work continuously with 100% duty cycle.

Compared to machines with first generation technology, second generation technology is more suitable for large power machines to get higher reliability.

Due to the adopting of advanced technology, SP-25BD, SP-35B and SP-45B series machines are acterized by larger frequency range, smaller size, water cooled transformer, higher reliability and lower repair cost.

Location:

Location:

Medium frequency induction heating machine

Medium frequency induction heating machine

Company address

Company address