Medium frequency induction heating machine

Medium frequency generatormore >

Medium frequency Whole rod heatermore >

Medium frequency rod partial heating machinemore >

other rod heating applicationsmore >

Medium frequency melting furnacemore >

Typical applications of melting furncemore >

Other M.F. design and applicationmore >

Medium frequency induction heating machineintroduction

SPZ series Medium frequency induction heaters are acterized by frequency range 200HZ~20KHZ and power15~600KW,they are mainly used for penetrated heating, such as rod heating for shaping, melting, fitting and preheat for welding. Due to its wide frequency range, satisfied heating effect is easily achieved by design to considerate all factors such as penetrating desire, heating efficiency, working noise, magnetic stirring force and so on.

In SPZ medium frequency machines,parallel oscillating structure is used . IGBT module power components and our fourth generation inverting control technologies are applied to ensure high quality and reliability. Fully protection is adopted such as over current protection, water fail protection, over temperature protection, over voltage protection, short circuit protection and phase fail protection. When working, output current, output voltage , oscillating frequency and output power are all displayed on the operating panel to help in the design of the coil and adjust of the machine.

According to different usage, two main structures are used:

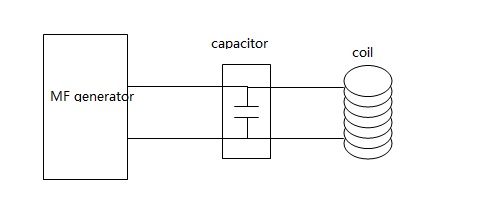

(1) structure 1 :MF generator + capacitor + coil

This structure is adopted often in many uses, such as rod heating machine and melting machine. This structure is simple, low lost and high efficient in heating.

In this structure, usually 3 to 15 meters copper tube is needed to make the coil; voltage of the coil is high to 550V, and not isolated to the power supply system, so coil must be insulated properly to ensure the safety of operators.

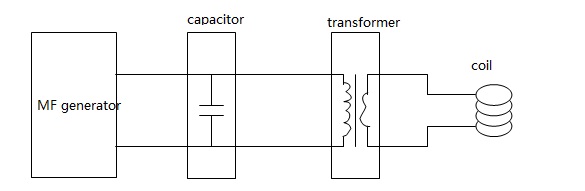

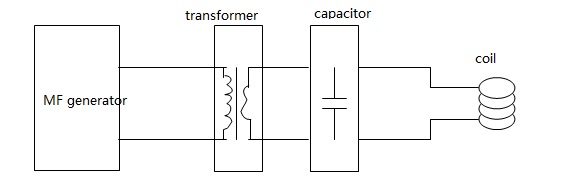

(2)structure 2:MF generator + cap + transformer + coil

This structure is also used often, such as melting in vacuum, medium frequency induction quenching and so on. Through the design of transformer ratio, output current and voltage can be controlled to satisfy different heating desire.

In this structure, coil is safe for operators, coil tube can exposed directly with out insulation. Coil is easy to make with only a few turns. Of course, transformer will increase the cost and consumption the machine.

2、 Advantages of SPZ series machine

(1) In SPZ medium frequency machines,parallel oscillating structure is used . IGBT module power components and our fourth generation inverting control technologies are applied.

(2) Wide frequency ranges from 1KHZ to 20KHZ, it is easy to match the machine according to the parts and heating desire.

(3) Due to the parallel oscillating structure, it is easy to get the best matching of the machine to get high heating efficiency and full power output of generator.

(4) Due to the high technologies of our fourth generation inverting control, soft and accurate switching control is realized to assure the high reliability and low repair of the machine.

3、 SPZ models meaning

SPZ-○○ X

SPZ: means shuangping medium frequency series

○○: rated input power

X: auxiliary function. A – with timer B—with transformer

4、 Main models

SPZ-15、SPZ-25、SPZ-35、SPZ-45、SPZ-70、SPZ-90、SPZ-110、SPZ-160、SPZ-240、SPZ-300 and SPZ-600

Location:

Location:

Medium frequency induction heating machine

Medium frequency induction heating machine

Company address

Company address